Every craft has its own set of procedures involved that requires a certain skill set, precision and techniques.

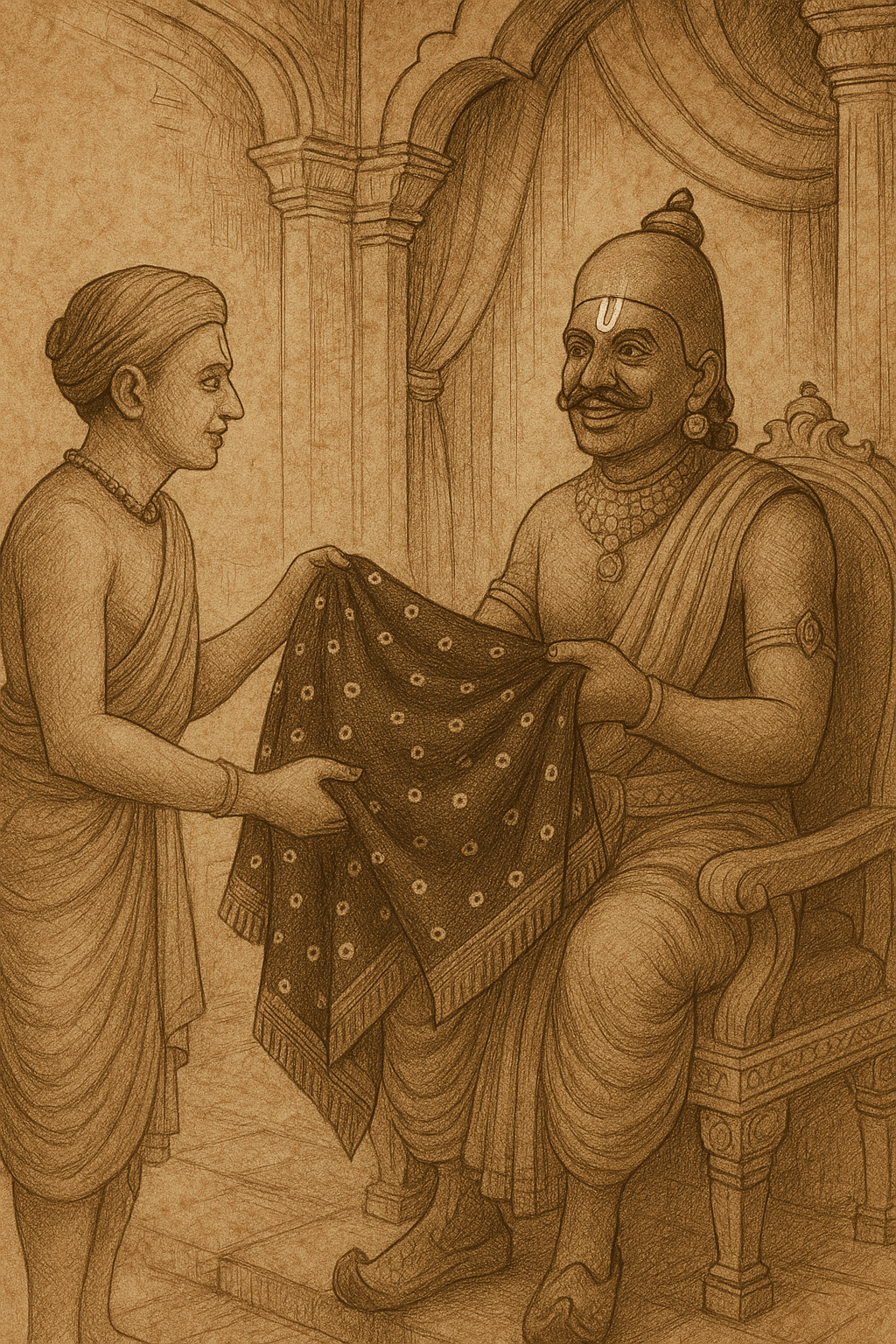

The Madurai Kaikattu sungudi is no different!

So today, I’ll take you through an immersive experience as you read through the process of how we create our Kaikattu Sungudi fabrics at Meippai, before turning them into beautiful classic silhouettes!

Step 1: Processing the gray fabric

Meippai indulges in conscious sourcing of premium cotton fabric that are washed, prepped and primed before starting the sungudi process.

Step 2: Marking the fabric

The prepped fabrics are then marked with specific designs as per requirement and distributed to the Kaikattu Sungudi Artisans along with all the other required supplements like cotton thread, design stencil and water soluble markers.

The artisans tie every single mark on the fabric as a knot with patience and precision.

Step 5: Fixing the color

Once the pieces are dyed and sent back to Meippai’s HQ, the Kaikattu Sungudi fabrics are prepped in hot water with rock salt and dried in shade to reduce color bleeding and fix the color.

Step 6: Opening the Kaikattu Sungudi knots

Finally, the dried Kaikattu Sungudi fabrics are stretched gently to remove all the meticulously hand-tied, Kaikattu sungudi knots tied by the Kaikattu sungudi artisans to see the beautiful pattern unfold.

The art of making Kaikattu Sungudi is currently facing a major crisis as it lacks artisans who are doing it. There are very few artisan left who are doing it continuously, hence resulting in very less production, unavailability and endless timelines to acquire it.

And with this unavailability of Kaikattu Sungudi artisans, this artform is completely confined to Sarees and Salwar sets mostly, diminishing its scope to be experimented with.

Now, how does MeippaiByNc play a role in supporting Kaikattu Sungudi?

MeippaiByNC empowers women of Madurai by fostering creativity and self-reliance through handcrafted Kaikattu Sungudi training. In the longer term, we are also looking forward to tying up with NGOs and organizations that share similar interests.

By this, I personally believe that a strong community of empowered Kaikattu Sungudi artisans can be built around this artform as it slowly starts to hold its ground. Currently Meippai has developed a community of around 15 Kaikattu Sungudi artisans.

Through this brand, as a designer, I look forward to experimenting with Kaikattu Sungudi in classy, wearable silhouettes and to combine other art forms with Sungudi in future to create pieces that showcase mixed media.

Meippai approaches “Sustainability” by curating consciously and by avoiding overstocking of materials as I believe in sourcing only as per our requirements and keeping it a made-to-order brand, to avoid wastage and to produce mindfully.

And as I tread through this journey, discovering more about Kaikattu Sungudi, other artforms and myself, I, along with my team, am intending to create with nothing but creativity, love and compassion.